Silicon carbide rods(coating)

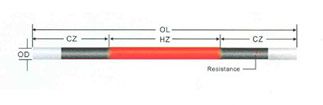

- Type: ED

- Cold end length: CZ, mm

- Outer diameter: OD, mm

- Overall length: OL, mm

- Hot zone length: HZ, mm

Description

Silicon carbide rods (coating) are a modern solution for high-temperature environments requiring enhanced durability and protection. The additional coating layer significantly improves oxidation resistance, minimizes heat loss, and prolongs the operational lifespan of the rods. These advanced components are ideal for industrial systems exposed to extreme thermal and chemical stress.

Extend Equipment Life with Silicon Carbide Coated Rods

In the world of industrial heating, durability and efficiency go hand in hand. Silicon carbide coated rods provide both, offering superior thermal performance along with a protective outer layer that safeguards the core material. This innovative design is essential for applications where exposure to oxygen, corrosive gases, or abrasive particles is unavoidable. The coating acts as a shield, preserving the structural integrity of the rod while ensuring stable operation over long cycles. Whether you're working in metal processing, ceramics production, or glass treatment, these enhanced rods offer the resilience required for consistent performance under pressure. Unlike standard SiC elements, silicon carbide rods (coating) have a specialized surface treatment that increases resistance to high-temperature oxidation. This makes them particularly valuable in environments where unprotected rods may degrade or lose efficiency over time. The coating reduces surface wear, preventing material loss and thermal fluctuations, which ultimately leads to better energy control and process stability. The use of coated rods also helps minimize downtime. Since the outer layer protects against common forms of degradation, these components maintain their heating capabilities longer and require fewer replacements. This translates into operational cost savings and improved equipment uptime, which are critical in fast-paced industrial settings. At Elheater, our silicon carbide coated rods are manufactured using high-purity SiC materials combined with advanced coating techniques. The result is a heating solution that performs reliably at temperatures up to 1600°C while resisting corrosion and mechanical damage. Each rod undergoes strict quality checks to ensure optimal functionality and compatibility with various system requirements. Our coated products are available in a wide range of configurations, including straight, U-shaped, and spiral forms. This allows you to select a rod that fits your furnace design and heating profile perfectly. The coating is evenly applied to ensure consistent protection across the entire working surface, eliminating weak spots and extending service life. Whether you are designing a new high-efficiency system or replacing aging components, choosing silicon carbide coated rods provides measurable advantages. Their enhanced protection and stable electrical characteristics support precise temperature control and reduce waste heat, improving overall productivity and system safety. In addition to offering the rods themselves, Elheater also provides expert guidance in selecting compatible accessories and installation techniques. Our team works closely with each client to recommend solutions that meet both technical and economic needs. Trust Elheater to deliver coated SiC rods that push performance boundaries while protecting your equipment investment. With our advanced heating components, your systems will run longer, more efficiently, and with fewer interruptions — exactly what modern industrial operations demand.Specifications

Details