Thermal Equipment

Full Package Solution For Lab Equipment - All For Your Researching. Sample processing, Biochemical testing, New material researching etc...

See Products

Who are we

Elheater is one technology orientated organization, team members are devoted to probing the most efficicent and reliable technology and innovations in the scienticfic researching equipment, fields like biochemical reacting, new materials researching, heat treatment, vaccum creating, refrigerating, as while as pharmaceutical and petroleum extracting equipment.

Ensure Best Quality from Source

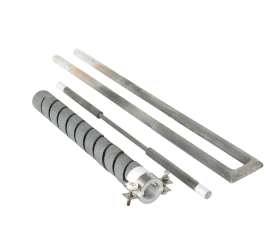

The best heating element for a furnace is one that is carefully chosen. This is based on the furnace’s specific operational parameters. The selection process involves a detailed analysis of the material properties, design, and compatibility with the furnace’s environment and operational requirements.

Engineers

Cases

Company profile

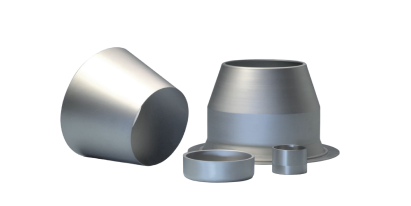

The main products are Mosi2 heating elements, Sic heating elements, industrial furnace, tungsten and molybdenum materials and products, pharmaceutical butyl rubber stopper,etc.

FAQ /

Conversely, for higher heat output, thicker elements with lower resistance are preferred. This allows more current flow.

Conversely, for higher heat output, thicker elements with lower resistance are preferred. This allows more current flow.

Conversely, for higher heat output, thicker elements with lower resistance are preferred. This allows more current flow.

Conversely, for higher heat output, thicker elements with lower resistance are preferred. This allows more current flow.