Mosi2 W type

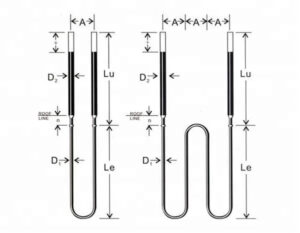

- Material Grade:1700,1800

- Diameter:D1/D2,mm/mm

- Hot zone length:Le,mm

- Cold end length:Lu,mm

- Shank Spacing:A,mm

Description

Mosi2 W type heating elements are engineered for the most demanding thermal applications where performance, reliability, and high-temperature stability are non-negotiable. With their distinctive triple-leg construction, these heaters ensure consistent power distribution, extended lifespan, and optimal performance in industrial environments that operate at extreme temperatures.

W Shape MoSi2 Heating Element: Engineered for Extreme Operating Temperatures

In high-heat industrial operations, w shape MoSi2 heating element designs offer a dependable solution when standard heating rods are no longer sufficient. Built from molybdenum disilicide, these triple-leg elements are ideal for furnaces requiring uniform temperature distribution, excellent oxidation resistance, and continuous operation at temperatures up to 1800°C. The Mosi2 W type configuration consists of two heating legs and a central support leg, forming a structure that enhances mechanical stability and thermal balance. This design is particularly advantageous for vertically installed heating systems or furnaces with deep chambers where structural support and uniform heating are both essential. Each w-type molybdenum disilicide heating rod delivers precise and reliable heat transfer, even under frequent cycling and harsh atmospheric conditions. Whether used in glass production, advanced ceramics, metallurgy, or material testing, these components support consistent process quality while minimizing energy loss and mechanical stress on the heating system. Thanks to the unique self-forming silica layer that develops during operation, these rods offer impressive protection against oxidation. This natural barrier increases the service life of the element and reduces the need for maintenance, helping to minimize downtime and total cost of ownership. At EL Heater, we manufacture w shape MoSi2 heating element solutions to meet various power ratings, voltages, and furnace configurations. Whether you require custom dimensions or standardized components, we ensure each product is crafted with attention to dimensional precision, electrical resistance, and material integrity. The triple-leg design of mosi2 w type elements also allows for enhanced thermal coverage. The balanced layout of heating zones reduces the likelihood of cold spots or uneven heating, which is vital for processes that depend on thermal uniformity. This translates to improved product consistency and reduced material waste. Installation is straightforward and flexible, with mounting options suitable for both new systems and retrofits. The cold ends remain outside the hot zone, enabling safer electrical connections and easier component handling. Combined with our optional accessory kits—terminal clamps, support fixtures, and connectors—system integration becomes efficient and secure. Choosing w-type molybdenum disilicide heating rods also means choosing longevity. These elements can operate continuously in oxidizing or inert environments without significant degradation, making them an excellent fit for industries with strict uptime requirements. The thermal shock resistance of MoSi₂ ensures reliable startup and shutdown cycles without structural failure. Whether you are upgrading existing infrastructure or designing a completely new heating solution, our mosi2 w type components bring together strength, precision, and high performance. Backed by expert technical support and a commitment to industrial-grade quality, EL Heater offers the solutions you need to reach new levels of thermal reliability.Specifications

Details