About Us

Full Package Solution For Lab Equipment - All For Your Researching. Sample processing, Biochemical testing, New material researching etc...

Making Hard Materials that

Make You Better

Elheater is an established specialist for high-temperature technology. Since 1996, our family-owned company has been producing and selling economic while also high-quality metallic-ceramic solutions for sintering, firing and melting, as well as heat treatments.

In combustion or electrically operated industrial and laboratory furnaces: Our products, components and systems work safely at temperatures of 560°C to 1800°C. From tried-and-tested standard products for high-precision firing process control to individual special productions for electrical heating or thermal insulation, we supply standardised and customised solutions to customers from around the world from industrial applications and production as well as research.

Industrial Experience

We have more than 12 years of experience in refractory metal processing, and we have very mature processes for processing tungsten, molybdenum, tantalum, and niobium materials.

We can process and produce whether it is tungsten or molybdenum products for semiconductors or tungsten, molybdenum, or tantalum parts for high-temperature furnaces.

Advanced Equipment

Elheater is an established specialist for high-temperature technology. Since 1996, our family-owned company has been producing and selling economic while also high-quality metallic-ceramic solutions for sintering, firing and melting, as well as heat treatments.

In combustion or electrically operated industrial and laboratory furnaces: Our products, components and systems work safely at temperatures of 560°C to 1800°C. From tried-and-tested standard products for high-precision firing process control to individual special productions for electrical heating or thermal insulation, we supply standardised and customised solutions to customers from around the world from industrial applications and production as well as research.

Quality First

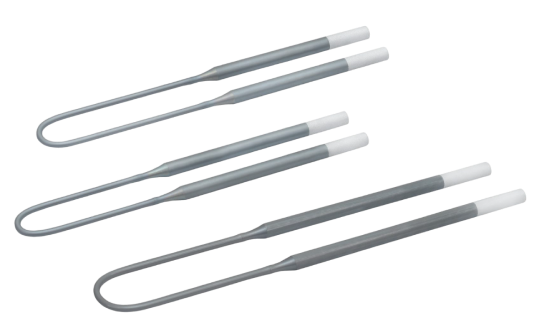

Sic heating elements

Enhance Your Furnace Efficiency with Silicon Carbide Heating Elements

When it comes to ensuring optimal performance in thermal systems, silicon carbide heating elements offer a top-tier solution. These advanced components are engineered to withstand extreme environments, making them ideal for processes that require stable and high operating temperatures. Used in industries such as ceramics, metallurgy, and glass production, SiC-based devices deliver consistent heating, reduced downtime, and significant energy savings. Manufactured using a blend of cutting-edge technology and quality raw materials, these elements offer excellent oxidation resistance and minimal thermal expansion. Their unique structure allows for uniform temperature distribution, improving overall system efficiency. Unlike conventional heaters, SiC units maintain high performance over extended periods, which reduces replacement frequency and operational costs. One of the key advantages of using sic heating elements is their ability to function effectively across a wide range of temperatures, often exceeding 1600°C. This makes them particularly suitable for heat treatment, sintering, and other specialized processes. Their resistance to chemical corrosion also means they last longer in harsh environments, making them a smart investment for industries looking to maximize uptime and reduce expenses. While looking for sic heating elements suppliers, it's important to focus not just on cost but also on quality and support. At Elheater, we provide products that are rigorously tested to meet global standards. Our catalog includes various sizes and designs tailored to your system’s specific requirements. As trusted silicon carbide heating elements suppliers, we ensure each item is optimized for performance, reliability, and longevity. When considering the sic heating elements price, buyers should evaluate long-term value. While initial costs may vary depending on specifications and type, the durability and efficiency of SiC heaters often translate to substantial savings over time. At Elheater, we balance affordability and quality, offering competitive silicon carbide heating elements price options without compromising on product integrity. Choosing the right heating component can dramatically influence your system’s performance. With a wide selection of SiC solutions in our inventory, we aim to help clients boost productivity while maintaining precise thermal control. Each product we deliver reflects our commitment to innovation, efficiency, and customer satisfaction. If you're upgrading your system or replacing outdated components, our team is ready to assist. From technical guidance to after-sales service, we support our clients every step of the way. Let Elheater be your reliable partner in sourcing top-quality silicon carbide heating elements designed for demanding industrial use.

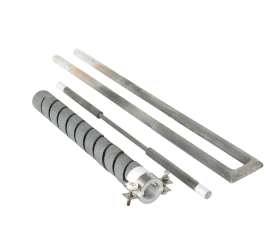

Mosi2 heating elements

Molybdenum Disilicide Heating Elements for Superior Heat Treatment

Industrial operations that demand intense and uniform heating rely on molybdenum disilicide heating elements for their exceptional thermal and mechanical properties. Capable of operating at temperatures up to 1800°C, these heaters are widely used in metallurgy, ceramics processing, glass manufacturing, and other high-temperature environments where standard solutions fall short. The key advantage of mosi2 heating elements lies in their ability to maintain stability across a wide temperature range. Made from high-purity molybdenum disilicide, these components form a protective silica layer during operation, which prevents further oxidation and prolongs lifespan. This unique characteristic ensures that your equipment maintains its efficiency even during continuous, long-term use. Another important feature is the low aging rate of the mosi2 heater, which enables consistent heating without significant changes in resistance. This leads to precise temperature control, minimized maintenance, and fewer production disruptions. Whether your process requires intermittent heating or continuous high-temperature cycles, Mosi2 elements are designed to deliver optimal results. At Elheater, we provide a broad selection of molybdenum disilicide heating elements, including standard shapes like U, W, and L, as well as custom configurations tailored to your specific furnace design. Each product is manufactured under strict quality standards to ensure thermal reliability, mechanical integrity, and operational safety. When considering the mosi2 heating elements price, it’s essential to evaluate not only the upfront cost but also the long-term value. Thanks to their superior durability and efficiency, these heaters reduce the frequency of replacements and energy waste, making them a smart investment for companies focused on maximizing uptime and reducing operational costs. Our catalog includes elements suitable for both laboratory-scale equipment and large industrial kilns. Every unit is tested for resistance accuracy, current tolerance, and material consistency. We also offer technical support to help you select the most suitable configuration, connection system, and accessories for your heating process. One of the key reasons professionals choose Elheater is our commitment to performance and reliability. Our Mosi2 components are trusted worldwide for their endurance, especially in environments with fluctuating thermal loads or aggressive atmospheres. These heaters resist thermal shock and offer a fast response time, enhancing both productivity and quality control. Whether you're upgrading an old system or building a new high-efficiency furnace, incorporating mosi2 heater solutions from Elheater ensures better energy management, longer equipment lifespan, and stable thermal conditions throughout your process. Contact our team today to learn more about the best options for your specific needs. With Elheater, you get more than just parts — you get lasting value and expert support every step of the way.

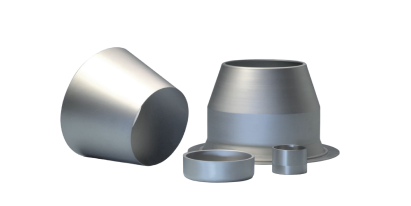

Molybdenum & Tungsten